We just wanted to let everyone know that Ford released a new design front brake rotor for the 2015+ S550 Mustangs that have the 4 Piston Front Caliper. This change was made a couple of years ago but there has been on going confusion of the correct part number. The original configuration was vented out at the front wheel rather than from the backside of the wheel. This has been referred to as 'reverse cooled' which is not accurate(it still centrifugally pumps air from the center up through the vanes to the outside OD of the rotor), more accurately it was front-side or wheel-side cooled. For the majority of Mustang owners street driving, this was never an issue. Mustang owners that wanted to Auto-X or Track their Mustangs in HPDE/Time Trials quickly found out heat management was an issue. While conventional ducted cooling to the hub would dissipate some heat through radiant cooling(Cooler air passing over the backside brake rotor will remove heat-Like blowing on a spoonful of hot soup), the issue was the inability to duct positive pressure air flow of lower temperature air through the cooling vanes to cool the braking surfaces evenly, from inside the rotor. This new rotor design, Ford Part Number: KR3Z-1125-J (Motorcraft Part Number: BRRF-448) is a direct replacement for all 2015+ Mustangs that utilize the 352mm x 32mm rotor used with the 4 piston caliper. This part has been available for a couple of years and recently checking stock with our distributors plenty are currently available. Being that is a "conventionally" cooled designed, where the air enters the rotor on the backside at the hub and exits via the vanes through centrifugal pumping, a conventional ducted brake cooling system will be as effective as previous generation Mustangs.

This rotor weighs 28-29 pounds, so it has plenty of thermal mass, and when proper cooling is installed it will be able to handle much more thermal load created by racing brake pads on track. Because this brake system is on the majority of Mustangs built since the S550 Chassis was introduced, you will likely be able to locate one quickly near your track event, even on a weekend, in case you need one. The other advantage to this new rotor is maintaining your stock 17-18" wheels, not being bumped to a new class due to a different brake system or wheel size. Consumables are also less expensive with this brake system. If you have your services performed at a Ford Dealer just confirm that they are installing this rotor during a brake service.

0 Comments

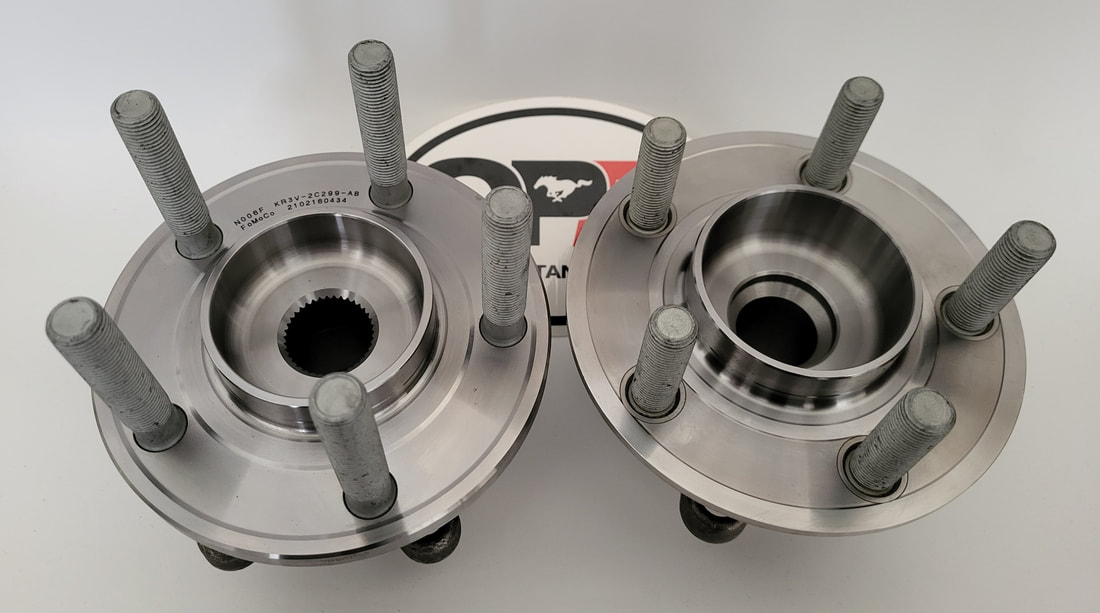

If you don't like words you can scroll to the bottom for the chart. We wanted to present some information on 2015+ Mustang Wheel Hubs, how to identify them and what to look for when you are upgrading your S550-S650 Hubs. When the S550 was launched in 2014, it came with many changes over the previous S197 Stick Axle Generation. The joke was always the S550 suspension was rocket ship technology over the previous version...because it finally had IRS, something the 1989-1997 T-Bird/Cougars and 1999-2004 Mustang Cobras had. Nothing really really earth shattering, except when you took a bone stock one on a road course and found out how easily it could be driven at the limit. With the new IRS came new wheel hub bearing assemblies, and 14x1.5mm Wheel Mounting Hardware over the previous 50+ Year run of 1/2"-20 wheel mounting hardware. Initially it was simple, there was one front hub, and one rear hub. We also use these front hubs on the 2005-2014 S197's. These are very common parts, (rear, very well known due to premature failures from lack of pre-load and some end user influenced shortened life spans) most of the aftermarket offers some form of a replacement part. Some of the aftermarket versions are pure and simply, absolute garbage with a name that unfortunately used to be a well known top quality brand. Upon the release of the GT350 / GT350R the hub situation became a little more complicated. This vehicle line introduced 4 new hubs, making the total 6 different hubs for the recently launched S550. We then quickly determined that there was really only one new hub, and everything else was just different wheel studs. Until we get to 2020, the rear hub is unchanged for all models when you exclude the wheel studs. We build hubs with our own wheel studs so we bulk purchase whichever number is available and priced reasonably. Ford has a habit of randomly changing prices for unknown reasons. Late last year we scoured the Country for GT350R front hubs because that week/month they were less than a standard Mag-Ride/GT350 Hub. In the past 7 years we have watched the prices with Ford, swing $50.00 week to week, on one hub. More than once have we bought up hubs because they were available only to find the next week they were $40.00/hub less, then a month later that part increases by $70.00. So we stockpile hubs and keep 30+ hubs of varying part numbers in inventory at any one time. We build a lot of hubs and if OEM wheel studs ever become highly valuable, I'm buying a boat like this...  When the Mag-Ride Option appeared in the 2018 Model Year refresh, we saw the GT350 NON-R front hubs make it to the rest of the Mustang line. That was simple enough, we now had a choice of 2 front hubs and still one rear hub for all S550 Mustangs. 2020 brought about the GT500, with a unique rear hub. This hub essentially took the MagRide/GT350 Front Hub Bearing Carrier and used the former rear wheel mounting flange. These are very easily identified by the much larger spline hole in the center of the hub for the larger axles on the GT500. The hub mounting flange changed from the square bolt pattern to the offset/spread bolt pattern from the front hubs. They do not interchange, they will not bolt up, the axle will not fit through the hole. Below is a side by side of the rear S550 Hub on the left to the GT500 hub on the right. As you can see in the pictures, the bearing has grown in Diameter about 6mm(0.240") which allows a larger drive axle shaft to be fitted. Interesting key points is the bearing width increased around 4.8mm (0.189") all inboard(toward the differential) which provides a fulcrum load capacity advantage (the wheel has less advantage). The GT500 hub uses the spread bolt pattern from the front hubs, and these flanges are also 1.27mm(0.050") thicker, which allows more structural integrity. The mass of the hubs increased from 3.59kg(7.92#) to 3.93kg(8.66#) so adding about 0.34kg(1.5#) to the rear of the car. All of this increase in size and mass increase heat and load capacity. All those advantages are great(except you bascially need a GT500 complete rear subframe assembly to get all the other parts to make these hubs work), but the biggest improvement is the rear axle bearing is pre-loaded!!! That rounded lip you see is the wheel flange/drive spline all as one component, that is press formed setting the bearing pre-load. I expect this to virtually eliminate rear hub bearing failures, caused by loss of axle nut torque. The 2024 Mustang uses the GT500 hubs, so +1 on the S650. Around March 1st, 2021 Ford quietly changed the front suspension on the S550 with the release of the MACH 1. It is still unclear if these changes carried over to other S550's with Mag-Ride or not. We do not even know if the non-handling pack Mach 1's received this suspension change. We only know this because of a hub debacle we had, with what turned out to be a very, very patient and understanding Customer. I would fire Ford's Marketing Department on the MACH 1, as you will see later. What we eventually figured out was that Ford redesigned the front Mag-Ride Knuckles, improving the steering geometry(Longer Levers-aka 2020 GT350R/GT500), more material around the front hub/bearing mounting area to further stiffen and strengthen the suspension...and to accommodate a completely different bearing hub assembly. GT350-GT500-Mag-Ride S550 Front hub on the left, MACH 1 Handling Pack(because we have no idea what other models they put these on) on the right. These hubs share the wheel bolt pattern and not much else. The Mach 1 bearing Diameter is around 92mm(3.627"), down from the previous 97mm(3.823") hub from the previous S550 years but has a 5.7mm wider bearing, placing the fulcrum advantage to the bearing rather than the wheel, just as in the GT500 rear bearing. They have gone to the thinner and lighter near net forged wheel mounting flange design, similar to the rear S550 hubs but it is also unique. The Hubs are lighter, 4.02kg(8.87#) vs. 4.33kg(9.54#)with most of the weight coming out of the wheel flange which is also a spinny part and anytime you can make the spinny parts lighter there is less inertia for accelerating, turning and braking. They drop .62kg(1.37#) from the front in just dead weight. The bolt pattern of the bearing mounting is also unique, not the same, not close. The mounting flanges are also thicker at 14.86mm(0.585") vs 13.34mm(0.525"). The thicker mounting flange is also due to the larger 14x1.5mm mounting bolts vs. the previous 12x1.5mm bolts to allow for a fastener diameter of thread engagement. One Point about these bolts, currently they are not available from Ford, clean the old ones and apply some thread locker and torque them to spec. They are not Torque to Yield (TTY). Ford also has no idea what the correct mounting bolt part number for the MACH 1HP/S650 Hub is, the parts system still shows the 12mm bolt which is Part Number W714333-S439(Also not available) The correct 14mm hub mounting bolt part number is W721525-S439. There are 2 currently in the world, which is odd because they are all sold in sets of 4. The only reason we know the correct part number is because Leo@Capaldi Racing was able to research it and provide it to us. Very beefy construction, because its the front hub directly out of the 2020+ 2WD Ford Explorer, an SUV with 5000+ pound towing capacity. These are designed to be very robust and that's why the mystery suspension from the MACH 1 HP is essentially what will be in the 2024 S650 Mustangs. Why Ford would not advertise that I'll never figure out. "Hey, we are building your car with parts from our future model, you get the best before everyone else" Close up of the GT350/GT500/Mag-Ride Hubs from 2015-2023* Splined internally. This is a close up of what we are calling the MACH 1HP/S650 Hub. No splines internally. The PDF below gives links to the hubs we offer for each specific Mustang Model. EDIT: 4-19-2023 We have since discovered since publishing this that it appears AT LEAST 2022 PP1 (Performance Pack Level 1 (Non Mag-Ride) Mustangs also come with the New Mach 1 HP Hubs and Knuckles. We are not sure exactly if its only ECO/GT PP1's or All Models. Our assumption is Base ECO/GT get the conventional knuckle with the single center nut hub, and the PP1/PP2/Mach 1 all received the New Knuckle and Hub.

Friends and customers, we have come to a crossroads in our business that requires some major changes to our communications and procedures moving forward. While we appreciate everyone's enthusiasm and support for our services, we find ourselves overwhelmed by the many different avenues of communication, which have become impossible to keep track of as our business grows. Living in today’s world, where everyone is constantly connected, it has become normal to send messages to a company or individual at all hours via social media, text, etc and expect an immediate response. We will no longer be able to continue down that path.

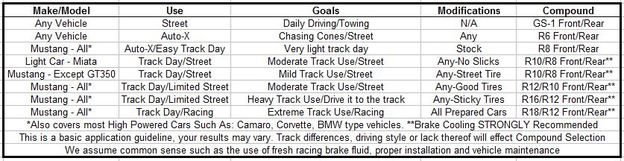

**Official hours for the time being are 8am to 5pm EST.** Please limit all communications via a phone call or email during our business hours. Calling on the weekend or after hours is acceptable if you really need help. Be honest with yourself about whether your issue can wait until Monday or not. All emails from the weekend will get a response by the following Monday. Our Email address is [email protected]. We will not respond to social media messages moving forward. If you call, please leave a voicemail and we will get back to you as soon as possible. Please feel free to follow that up with an email to us, those are much less likely to be missed because both Kelly and I see them. If you email, please feel free to send photos to give us a rough idea of what you are looking to have answered (visuals always help). All orders are typically shipped the same day or the next day if it is in stock. As much as we try to have everything in stock we rely on multiple vendors all across the country. We offer products that are made in small batches and require lead times to have made. We do not control the time for these products to be manufactured. We forecast demand based on sales. To keep up with demand, we have increased our purchase levels as well as the frequency of orders and this places a severe strain on the manufacturers and vendors to meet our deadlines. A manufacturer typically will perform most operations in house but not all operations. An example of this is anodizing and heat treatment processing. These are very specialized operations therefore are usually sent out to a third or forth vendor to be completed. Our vendors are at the mercy of their vendors, which places us near the bottom of the chain. If you need a product immediately we ask that you send us an email. We always work to fill emergency orders; we have the best Customers in the World. We have Customers who were not in rush, and graciously allowed us to to ship products from their order, which they have already paid for, to fill orders for another Customer. From the bottom of our heart, we do not know how we are this fortunate to have a Customer base as understanding and generous as you all are. Since we are a two-person operation, and much of our work is custom, we will have to give you a "window" for your shipment. If you have a deadline for an event and we promise to meet it, we will still do that as always, but will need advance notice. Please don't be offended if we are straightforward with you and tell you outright that we cannot do it. We hate to lose your business, but would rather lose that sale to another shop than let you down by missing an important deadline. Please plan ahead 3 weeks in advance, if possible. We have multiple open projects that have been dragging on for 2 years due to time constraints. We have 6 products we have been unable to complete because our time resources are constantly eaten away by social media. The main idea here is that we care very much about the quality of the service we provide, and care just as much about all our customers, who we consider friends, but some reasonable structure and boundaries need to be set so that we can have some semblance of life outside of this to spend uninterrupted time with our friends and families. We also hope to keep our passion and drive so we are able to provide excellent products and services to you for years to come, but at this pace burnout is imminent. Kelly is usually working 16 hours a day, I am usually working 20 hours a day and we no longer can support that. We understand that we have Customers all over the World in very different time zones, we have many fine Men and Women serving us overseas so we will continue to support them as long as everyone understands the responses may not be immediate as they were in the past. We take full responsibility for this since we have allowed things to be "loose and free" for so long, which is why we are being proactive about changing things for the benefit of everyone. Thanks very much for taking the time to read, we appreciate all of you, and we hope to have the opportunity to help you build something awesome in the future. Sincerely, Kelly and Tim Hilliard Optimum Performance P.S. A huge thank you to LeVel Motorsport, Glendale, AZ for allowing us to borrow much of the above.  We are asked this question multiple times a day and for good reason. There are several variables involved in choosing a proper brake compound. G-LOC offers 8 different Compounds in their product line range so choosing the correct compound for YOUR specific application can appear daunting. We are going to cover the basics so you can answer the questions yourself. 1. Obviously Year/Make/Model/Specific Brake System i.e. Brembo 4 piston, 6 Piston, Iron Rotors, Carbon Rotors etc. If it has a Non-OEM Brake System on it, knowing the caliper model or pad shape will be information you need to know along with pad thickness if it is a race caliper that allows endurance pads that are typically in the 25mm range. 2. What is the intended use? Daily Driving, Street Driving/AutoCross, Street Driving/Track Day, "It sits in the garage and I drive it to my track-day", "I trailer it to the track" Time Trials, Racing. 3. What are YOUR Goals? "I can't stand the brake dust and noise" or "The factory pads lasted one day at my last event and now I have a brake pulsation" 4. What have you done to your car? What tire - specifically, suspension - stock or adjustable coilovers with full adjustments, brake fluid, brake cooling. To answer these questions honestly and realistically helps in successfully choosing the proper compound. Lets run through a couple of examples. 1. 2017 Shelby GT350 2. I drive it mostly on the street. 3. The brake dust is horrible, constantly cleaning my wheels! 4. Stock because it's amazing. In this case G-LOC's GS-1 Compound would be the perfect choice. You would not compromise braking performance on the street, the compound is low noise, low dust with a very high bite that will still give you factory level braking on the street. We will let you in on a secret, all brake pads dust otherwise they would not stop the car. G-LOC compounds use materials that do not attack finishes so typically the dust just wipes off. The GS-1 compounds have a very low rotor wear rate, known as "rotor friendly". This prevents metal from the rotor from etching into wheel finishes. 1. 2017 Shelby GT350 2. I drive it occasionally but mostly do track events 3. The stock pads are ok but I find near the end of the session they begin to fade and I'm on my third set of pads. I am more comfortable in the car and I find myself pushing the braking every session. I think I need something with more bite and something that won't fade. I'm used to brake dust but want something that will still work on the street. 4. Stock MPSS's. I do not plan on changing to a track tire. In this case we can go in two different directions. The R12 Compound offers an extremely high bite, a large temperature operating range, it can be driven on the street and in this application would be a great starting point for someone to transition to a race compound pad. It will make noise and dust but it will shorten braking distances and used properly, not fade. You could also go to an R16 compound which is going to have a higher level of bite and temperature capability than the R12 but while it can be driven on the street it is best for the "I drive my car to the track, most of the time it is strictly a track toy" person. When you begin to look into track/racing brake compounds you need to look at balancing brake bias. What we mean by this, using the above GT350; a heavy car with huge speed potential, grip and massive brakes you need to balance the braking front and rear. Most cars are typically biased towards the front because under braking the front tires have most of the grip. The rear typically gets light so in a modern car with ABS the computer does most of that work for you. When you install a track/race compound on the front you will change this bias. The higher friction level of the pad will move more brake bias up front. If you leave the stock rear pads in place and run an R12 or R16 up front the front brakes will begin to do all the braking. This leads to very hot front brakes, high pad wear and sometimes a very unstable experience in a heavy braking zone. Matching the rear compound to maintain the factory brake bias will make the car faster, the brakes will maintain temperature and the pads will wear much longer. How do you match a rear compound to your fronts? Generally speaking, choose a compound one or two steps down from the front. Examples from above R12 front with an R10 rear. R16 front with an R12 rear. One of the advantages with the G-LOC pad compound choices is you can adjust this to your driving style and car set-up. You can add more rear pad if you have rear downforce or trail brake. This will give you more rear bite. If you find your style of trail braking is inducing too much oversteer you can also run less rear pad. There are many combinations you can run R12/R10, R12/R12, R16/R12, R16/R10. Lets look at a few other scenarios... 1. 2014 Mustang GT with Track Pack - 4 Piston Brembo's 2. Autocross 3. I dream of orange cones in my sleep. 4. All sorts of camber and sticky tires The best choice for pure Autocross is the R6 front and back. The R6 is G-LOC's Autocross pad of choice. On Mustangs you can also run R8's. If you mostly chase cones but are thinking about trying a road course for the first time R8's will work as long as you drive within the parameters of the compound. 1. Miata - Lighter Momentum Cars 2. Street/Track Day 3. I like passing Mustangs in the turns, but I drive it everyday. 4. Suspension/Tires In this case you would want to start with an R10 up front balance with an R8 in the rear. The pads are mild enough on the street but still work very well on track. 1. S550 Mustang GT with the Performance Package/ 6th Gen Camaro 2. Street/Trackday 3. I don't record my laptimes and I don't want to swap pads..ever. I have had race cars in the past, very experienced but this is just to have fun with and I understand how braking works. 4 Stock, it is really a good chassis. This is pretty universal for most cars. R10 Fronts with R8/R10 rears. This is a very contested area because it requires restraint to some extent. If you go this route and then decide to put on some used slicks you picked up from a race team it may not turn out how you planned. Mustangs are heavy cars, if you have an instructor you will be stopping 4000 pounds for 20-30 minutes at a time. If you use these properly they will work very well for you. I personally run these on our S550. I have 6 track days on them and they still look new. I have reasonable expectations and have pushed the limits of them from time to time. Typically I find the limits of the street tire before the pad compound. 1. S550 Mustang GT/S197 Mustang GT/5th-6th Gen Camaro 2. I drive to the track. 3. I need to beat everyone else 4. I've ruined a perfectly good street car. Full suspension, roll bar, harness, seats, brake cooling and 'street tires' that last about 2 days because they are basically slicks. R16/R12 but you should change to R18's...when you get to the track or just buy a car trailer. In the same scenario above with any Mustang/Camaro/Corvette that is trailered to the track and not driven on the street and runs a Rival/Hoosier/Race Team Scrub Slick should always be on an R18/R12 combination. Even the GT350 on the Cup2 tire is so fast it can take advantage of the R18 friction levels. And now a message from our Lawyers: R18's are not to be driven on the street. They require heat to begin working plus they will just wear out pads and rotors quickly. Last Example: I want to drive my Mustang everyday to work which is a 100 mile round trip. On weekends I want to run Watkins Glen, what Compound do you suggest? In this case; which ends up being the case for most of our Customers who need to pay for their track days by driving the race car to work, you need to swap pads. There is no magical pad that will do this, many manufacturers will claim it, it is not based in reality. Pads sold to operate in two polar opposite environments will be a big steaming pile of compromises. G-LOC is not a marketing company, they are a hands on brake pad manufacturer. For true weekend warriors that need to get to work on Monday but want to win the HPDE trophy need to use a pad for each goal. GS-1's during the week and then swap on the track pads either the night before or at the track when you are bolting on your tires. While the initial investment is higher, the savings will be noticed in a short period of time. Running a more expensive trackpad only on the track greatly reduces wear. Running a street pad on the street greatly increases your sanity from a quiet pad. G-LOC compounds are all compatible with each other. You can run any compound on the same brake rotors. Swap the pads in and go, no bedding, sanding, separate track rotors etc. |

AuthorTim Hilliard - A Driving Instrutors Worst Nightmare Archives

April 2023

Categories |

|||||||||

RSS Feed

RSS Feed